Pattullo Bridge replacement project

Temporary Bridge Structures / Pattullo Bridge replacement project

Want to start a project

with infraMOD?

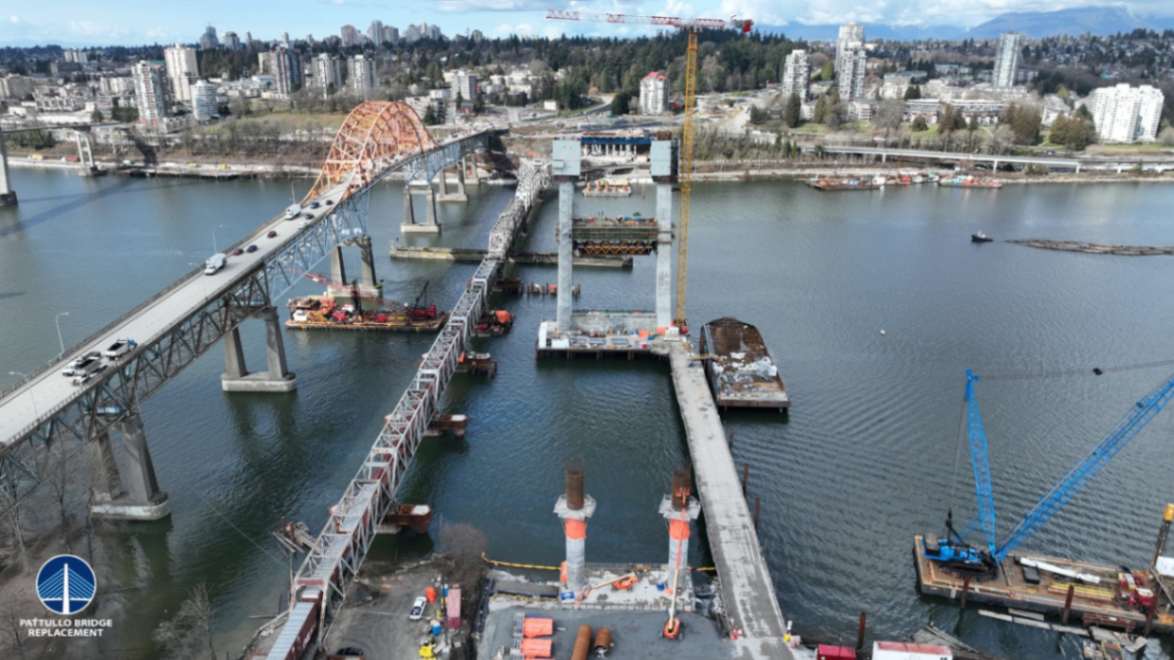

Project Spotlight: Pattullo Bridge Replacement Project

infraMOD was a key partner in the replacement of the essential Pattullo Bridge connecting Surrey and New Westminster, British Columbia, by providing over 1,200 tons of temporary steel.

SCOPE OF WORK

The Pattullo Bridge is a key connection between the communities of Surrey and New Westminster in British Columbia. The bridge originally opened in 1937, and construction is currently underway to replace the aging bridge. Construction is scheduled for completion in 2025, when the new bridge will open, and the existing one will be removed.

infraMOD was privileged to be part of replacing this essential bridge and allowing a critical connection to remain open between the communities. The new bridge will be a four-lane, toll-free crossing, and will provide several significant improvements for everyone, whether they are driving, cycling or walking.

Modern, wider lanes, separated by a centre median barrier will make crossing much safer, as will the dedicated walking and cycling lanes, which will be separated from traffic by a barrier on both sides of the bridge. The new bridge will also be more practical for the public, creating better connections to, from, and near the bridge.

infraMOD’s scope included:

- Drafting: Shop and Erection Drawings

- Supply: Material Procurement and Fabrication of ~1200 Tons of Steel

- Logistics: Planning and Delivery of ~40 Truckloads of Fabricated Modules.

SOLUTION

infraMOD was contracted to manage the supply of the temporary crane access trestles and work platforms for the North and South Piers. In total, infraMOD supplied and fabricated 1200 tons of steel for the Pattullo Bridge project. By utilizing our automated and robotic processes, infraMOD was able to assemble the trestle frames in an efficient manner, providing a lower cost solution to the customer. Thanks to infraMOD’s innovative solutions, the customer was able to complete the temporary bridge under budget.

HIGHLIGHTS

- Our large facility and laydown space was a big advantage for the customer. Being that the project took place in a congested urban area, access to laydown space was difficult; therefore, storage at infraMOD’s location was very valuable to the customer, helping the project to remain on schedule and avoid logistical challenges.

- By utilizing our automated and robotic processes, infraMOD was able to assemble the trestle frames in an efficient manner, providing a lower cost solution to the customer. Then enabled the customer to complete the temporary bridge under budget.

CHALLENGES

- To construct the in-river piers, it was necessary to have temporary access from the shore to the work areas. At the project’s outset, the customer did not have sufficient details to know how much the bridge construction would cost and therefore were forced to estimate an approximate amount for the temporary steel scopes; infraMOD’s approach created an efficient design and cost effective solution, keeping the project costs down.

- Being that the project took place in a congested urban area, access to laydown space was difficult; therefore, storage at infraMOD’s location was very valuable to the customer, helping the project to remain on schedule and avoid logistical challenges.

RESULT

- Despite the challenging circumstances of the project, infraMOD’s innovative solutions meant that the customer was able to complete the temporary bridge under budget.

- As always, infraMOD was able to add value to the customer in multiple ways and provide innovative solutions to the project’s challenges, through our design expertise, global supply chain, streamlined fabrication, comprehensive logistics management, and more. Leveraging our extensive project experience and this proven methodology, we delivered unique solutions that provided the lowest total installed cost, the shortest overall project schedule, and the lowest risk.