What We Do / infraMOD

infra

MOD

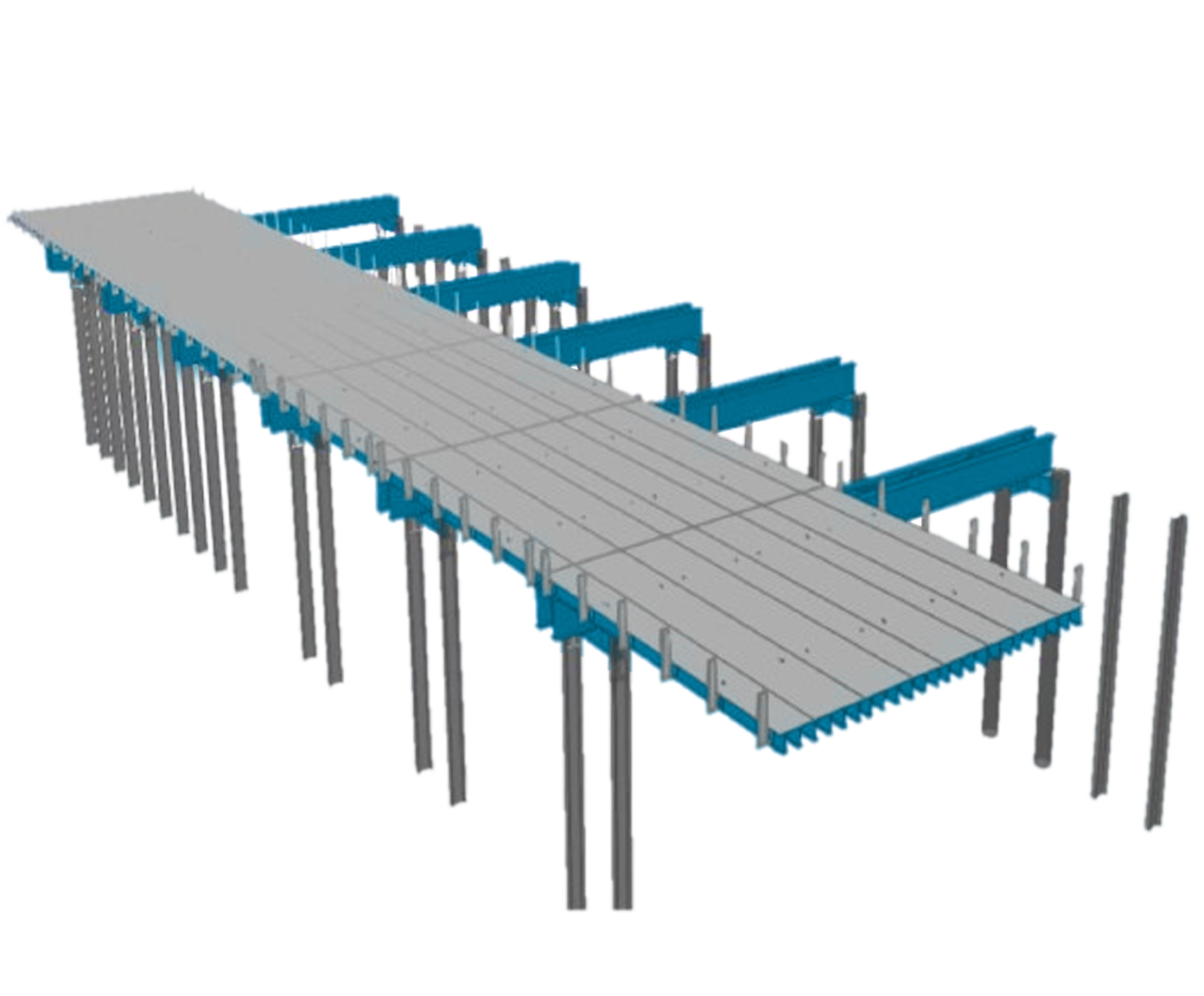

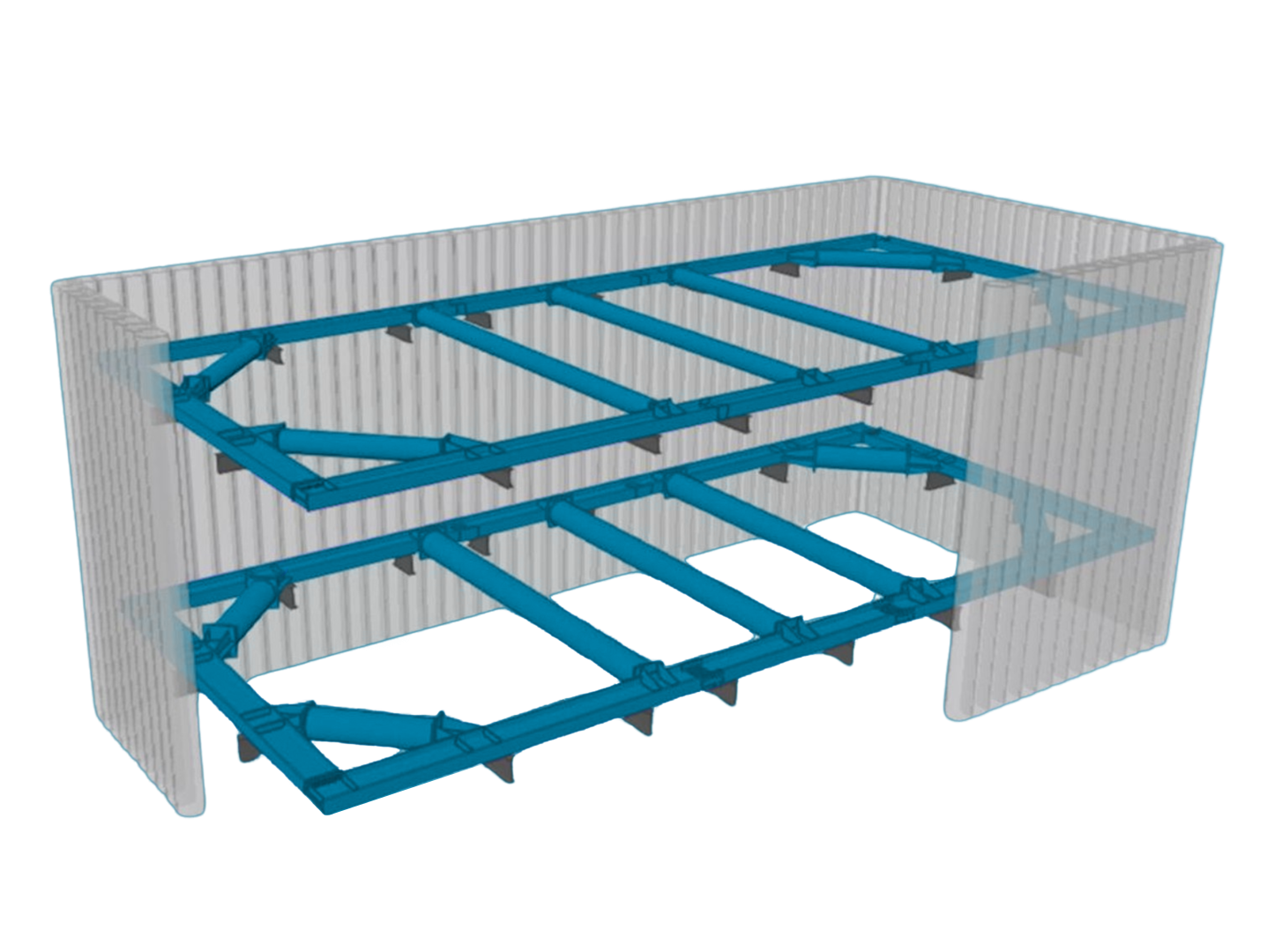

We offer efficient, modular solutions that reduce project timelines, cost and risks. Our modular systems includes walers and struts and equipment decking.

infraMOD™ is a revolutionary approach to temporary steel for infrastructure projects. It tackles the limitations of traditional methods by leveraging modular solutions, state-of-the-art technology, and innovative engineering.

Industry Challenges

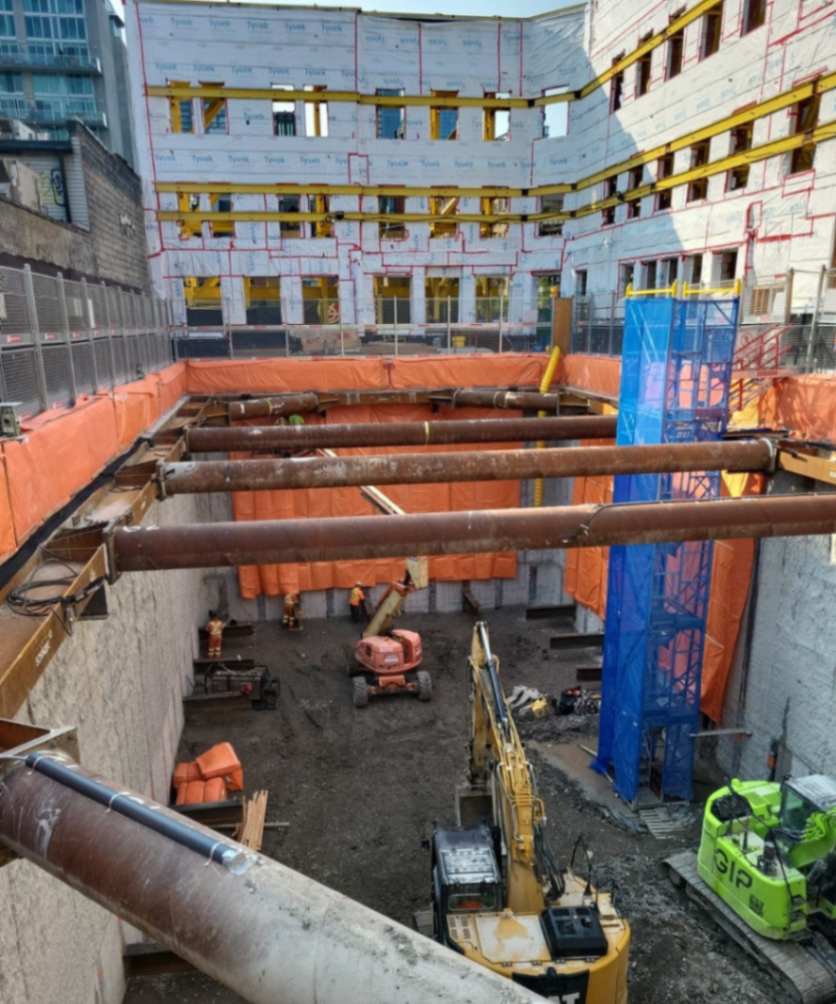

Traditionally, many temporary works solutions are developed with the intention of

performing most of the work in position, on-site during installation, which results in

many challenging constraints, such as:

- Work typically being performed by specialized/highly skilled resources with strictly managed quality.

- Difficulty performing welding on-site in poor weather and at construction sites that restrict hot work.

- Unacceptable project budget and over-all schedule for the actual cost and time required to perform the work.

- Scarcity of well-experienced resources.

- Growing demand to make quality control of on-site welding stricter.

infraMOD SOLUTIONS

Saskarc’s infraMOD design methodology is an innovative approach to minimize challenges

associated with temporary works on infrastructure projects. By combining our team’s

expertise, strategic sourcing, and state-of-the-art processes, we add value to your project

by providing unique modular solutions saving you time, effort, and money. These solutions

utilize standard pre-designed products, site-specific solutions, or a combination of both, to

provide a simple-to-assemble modular solution, designed for a quick and uncomplicated

installation. This reduces project duration, specialized site resources, and associated risks.

- Modular design allows adaptation to many geometries.

- Many components are identical, allowing for changes to installation sequences without risk of incorrect components on site.

- Quick delivery enabled by our FastArc and SpeedArc robotic technology, which produces our modular solutions with great efficiency while maintaining stringent quality requirements.

- Most fitting and welding is performed off-site in a controlled shop environment ahead of schedule, enabling it to be installed at site quickly by less skilled resources. This significantly reduces the site schedule while successfully reducing the total installed cost.

Features:

- Simple bolted connections between components.

- Elimination of welded shear connections between waler beams and king piles, minimizing site welds often performed in difficult conditions.

- The waler and strut system can be trial assembled in our shop, ensuring perfect fit-up during the installation process.

Speed of installation:

- Each system is developed in a three-dimensional model providing detailed visual installation plans, eliminating any doubt for the installation crew.

- Complete installation in just days, allowing the excavation to proceed earlier than planned due to a much shorter installation time compared to traditional welded design.

- Individual struts can be installed within 3-4 hours without any specialized equipment or resources.

- Easy changes to installation sequences.

- Quick installation and removal.

- Ability to quickly reconfigure layout of decking panels or provide quick temporary access through excavation.

- Support beams for modular decks can also serve as support of excavation elements, reducing overall quantity of temporary steel required.

- Highway rated Traffic Barriers (Guardrails).

- Low maintenance, slip resistant deck coating.

- Quiet operation.

- Aesthetically pleasing to the public.