Support of Excavation

What We Do / Support of Excavation

The Key To Infrastructure

Project Success

Reducing Costs, improving schedule & minimizing risks in SOE projects is what we do best. Experts in excavation support projects in North America, infraMOD offers modular solutions to solve highly complex temporary support of excavation problems.

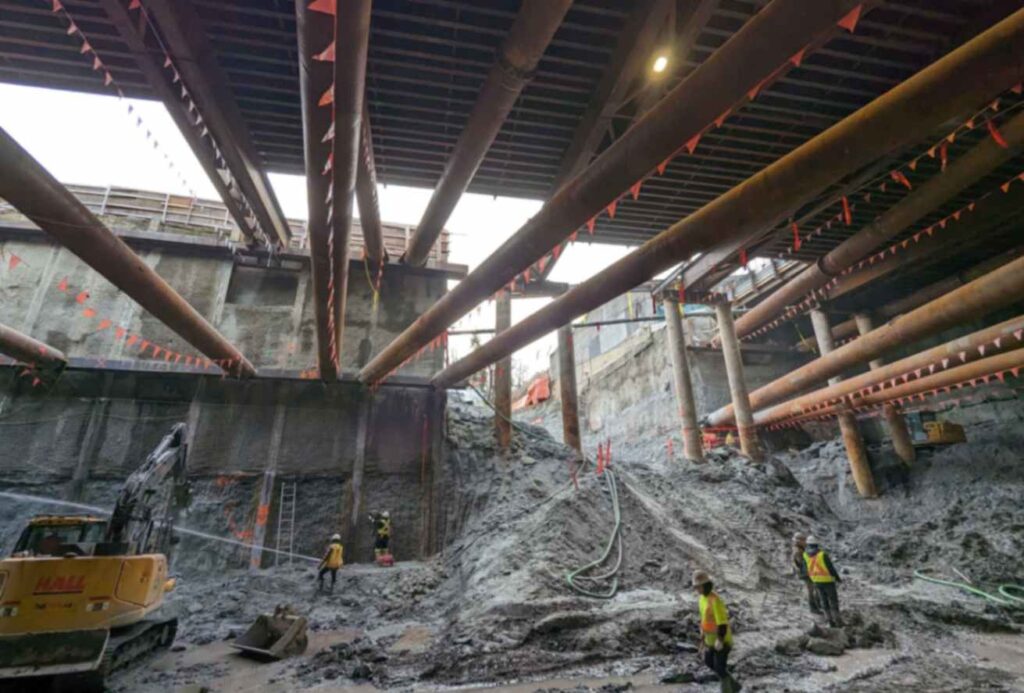

Support of Excavation, also known as temporary / early works in construction, are the activities needed to prepare a construction site for the main excavation works, also referred to as permanent works. These could include large infrastructural projects for transportation like subways, water and waste water tunnels, nuclear projects, and commercial projects.

Why is infraMOD the Leader in Support of Excavation Projects?

Designing Your Success

Most projects struggle with ballooning costs from improper SOE planning. Incorrect design, detailing and planning, leads to idling machines and workers, while incorrect material is sourced at high costs. Thanks to our infraMOD methodology, infraMOD’s support of excavation (SOE) steel solutions create a safer, faster, and more cost-effective construction process.

The Benefit of Site Experience

Our decades of experience, help us design and plan accurately for various site conditions. Projects often get stuck in site specific challenges and end up racking thousands of dollars as cranes & workers sit idle. Our battle tested solutions provide savings across the board for our clients. An unmatched benefit that makes us the leader in Support Of Excavation projects.

Cost Effective Steel Sourcing

While our engineered solutions save you time, our global steel manufacturing networks give us an edge sourcing material at competitive costs that are difficult to access. We leverage long-standing relationships with trusted suppliers across North America and overseas to secure quality steel. This means you get reliable material availability, consistent quality, and pricing that helps keep your project budget on track.

Modular Solutions Reducing Risk

infraMOD provides essential support during the early stages of a project, ensuring a smooth transition to the main construction phase. Offsite, modular fabrication that forms the basis of the infraMOD methodology means lower injury risks to workers on site, delays due to inclement weather and therefore reduced work stoppage risks.

Increasing Your

Success Rate

Projects see the greatest success when they include infraMOD at the very beginning. With early involvement in excavation support using our proprietary infraMOD process, we have helped projects reduce costs, improve project schedules and minimize risks.

infraMOD'S SOE SCOPE

If a project requires cut & cover or vertical shaft excavation, infraMOD is equipped to supply:

- Reusable Walers & Struts

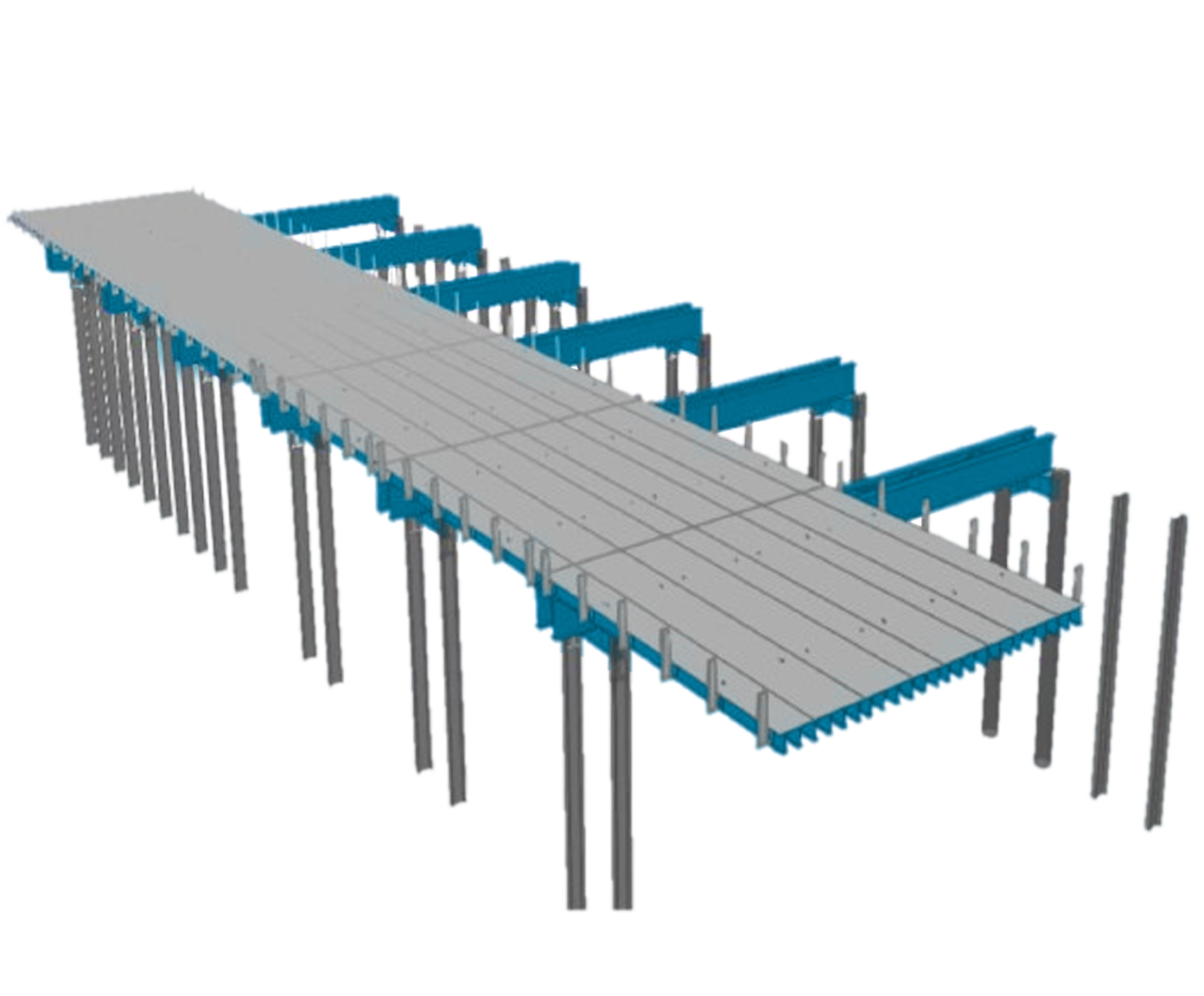

- Temporary Traffic / Equipment Decking System

- Temporary Walers & Struts

- Utility Trays / Supports and / or Pipe Supports

- Raw Piling Materials

- Tiebacks

- Tiedowns

- Soil Nails

- Micropiles

Industry Challenges

Traditionally, many temporary works solutions are developed with the intention of

performing most of the work in position, on-site during installation, which results in

many challenging constraints, such as:

- Work typically being performed by specialized/highly skilled resources with strictly managed quality.

- Difficulty performing welding on-site in poor weather and at construction sites that restrict hot work.

- Unacceptable project budget and over-all schedule for the actual cost and time required to perform the work.

- Scarcity of well-experienced resources.

- Growing demand to make quality control of on-site welding stricter.

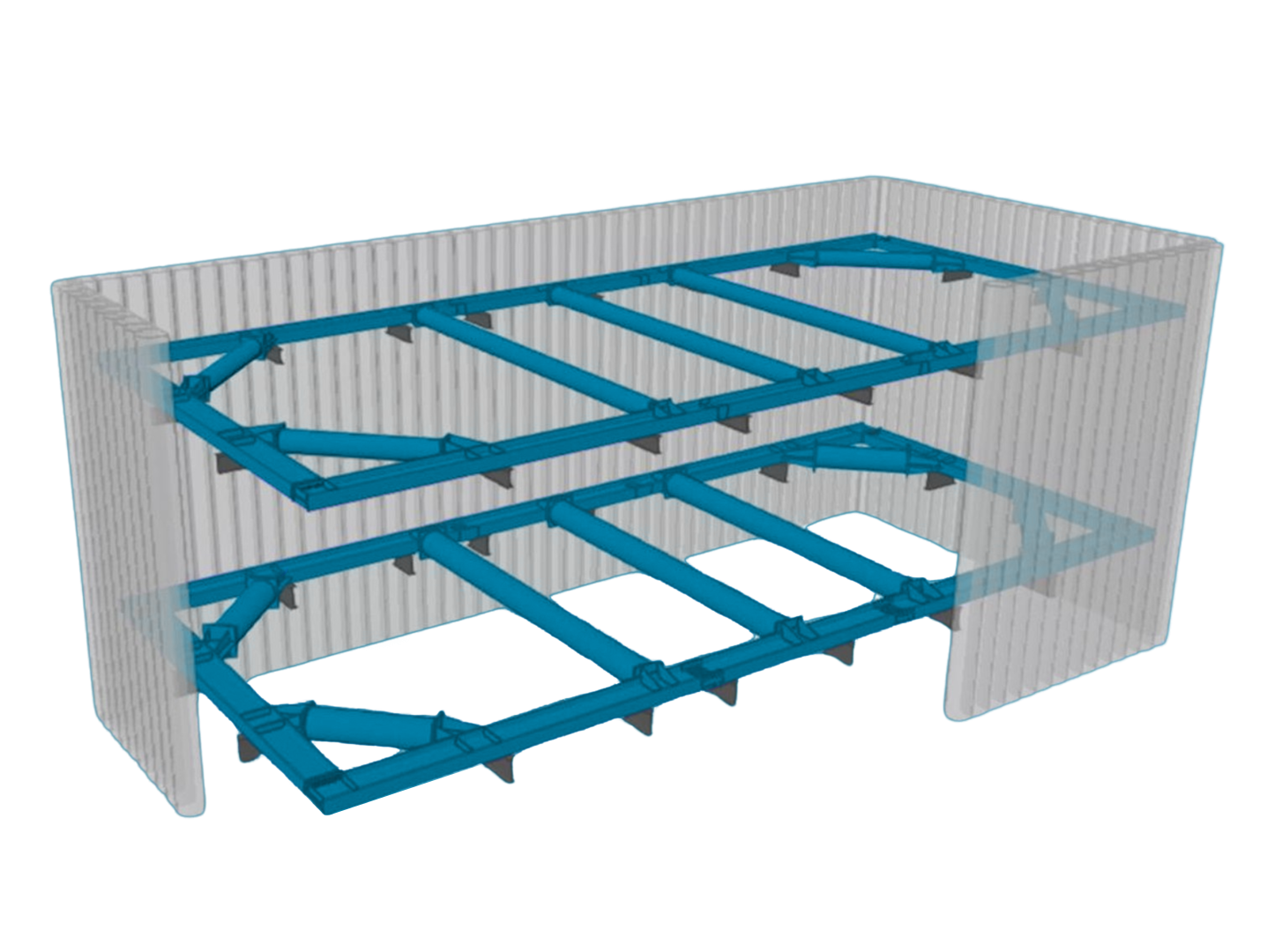

infraMOD SOLUTIONS

infraMOD design methodology is an innovative approach to minimize challenges

associated with temporary works on infrastructure projects. By combining our team’s

expertise, strategic sourcing, and state-of-the-art processes, we add value to your project

by providing unique modular solutions saving you time, effort, and money. These solutions

utilize standard pre-designed products, site-specific solutions, or a combination of both, to

provide a simple-to-assemble modular solution, designed for a quick and uncomplicated

installation. This reduces project duration, specialized site resources, and associated risks.

- Modular design allows adaptation to many geometries.

- Many components are identical, allowing for changes to installation sequences without risk of incorrect components on site.

- Quick delivery enabled by our FastArc and SpeedArc robotic technology, which produces our modular solutions with great efficiency while maintaining stringent quality requirements.

- Most fitting and welding is performed off-site in a controlled shop environment ahead of schedule, enabling it to be installed at site quickly by less skilled resources. This significantly reduces the site schedule while successfully reducing the total installed cost.

infraMOD's Support of Excavation Products

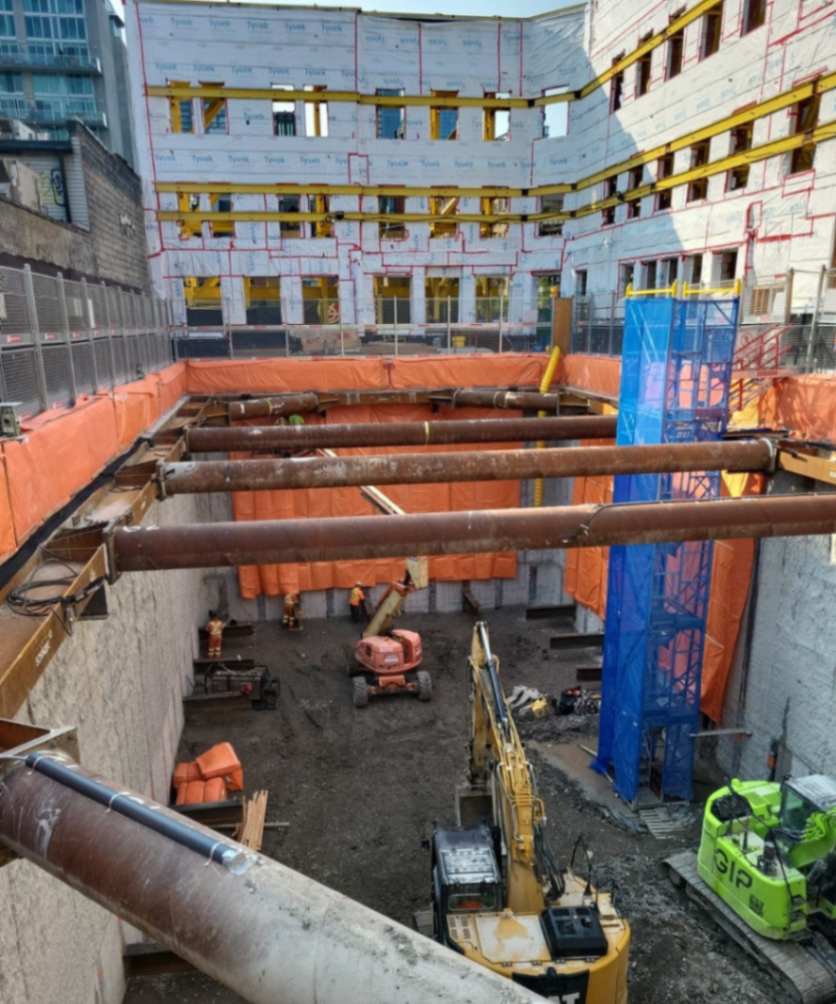

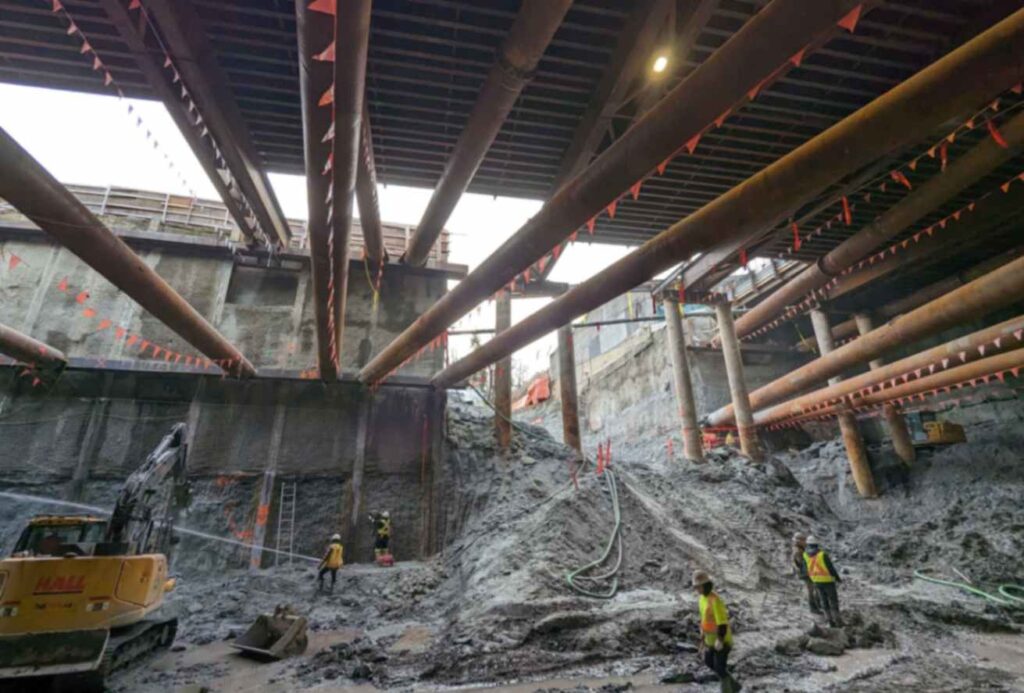

infraMOD’s modular solutions streamline installation, minimize delays, reduce unnecessary costs and keep worksites moving efficiently. Based on decades of experience on complex jobsites, we created modular steel products that optimize SOE projects for our clients.

Our infraMOD Struts & Walers are engineered for strength and adaptability, ensuring excavation stability on complex civil projects. infraMOD Traffic Decking systems provide safe, durable access for vehicles and equipment, even over active excavation zones. Backed by infraMOD’s engineering expertise, each product is designed to reduce risk while enhancing project performance.

Features:

- Simple bolted connections between components.

- Elimination of welded shear connections between waler beams and king piles, minimizing site welds often performed in difficult conditions.

- The waler and strut system can be trial assembled in our shop, ensuring perfect fit-up during the installation process.

Speed of installation:

- Each system is developed in a three-dimensional model providing detailed visual installation plans, eliminating any doubt for the installation crew.

- Complete installation in just days, allowing the excavation to proceed earlier than planned due to a much shorter installation time compared to traditional welded design.

- Individual struts can be installed within 3-4 hours without any specialized equipment or resources.

infraMOD'S SCOPE

Cut & Cover Construction

If a project requires cut and cover construction, infraMOD is equipped to supply:

- Temporary Traffic/Equipment Decking Systems

- Reusable Walers & Struts

- Temporary Walers & Struts

- Utility Trays/Supports and/or Pipe Supports

- Raw Piling Materials (Sheet, Pipe, HP, W Sections)

Vertical Shaft Excavation

If a project requires vertical shaft excavation, infraMOD is equipped to supply:

- Temporary Traffic/Equipment Decking System

- Reusable Walers & Struts

- Temporary Walers & Struts

- Utility Trays/Supports and/or Pipe Supports

- Raw Piling Materials

Tunnel Boring Machine (TBM)

If a project requires a tunnel boring machine (TBM), infraMOD is equipped to supply:

- Gallow Beams

- TBM Back-up Supports

- Easy changes to installation sequences.

- Quick installation and removal.

- Ability to quickly reconfigure layout of decking panels or provide quick temporary access through excavation.

- Support beams for modular decks can also serve as support of excavation elements, reducing overall quantity of temporary steel required.

- Highway rated Traffic Barriers (Guardrails).

- Low maintenance, slip resistant deck coating.

- Quiet operation.

- Aesthetically pleasing to the public.

Ground Anchoring Solutions

(Tiebacks. Tiedowns. Soil Nails. Micropiles)

infraMOD’s ground anchoring solutions are engineered to reduce risk, simplify installation, and support faster, more predictable excavation progress.

The new infraMOD ground anchoring and bracing solutions include:

- Temporary & Permanent Strand Anchors: High-capacity anchors designed for shoring walls, retaining structures, and slope stabilization.

- Tie Downs & Tie Backs: Engineered systems for securing structures against uplift and lateral forces, essential for foundations, towers, and industrial facilities.

- Soil Nails: A full range of soil nail systems for reinforcing cut slopes, excavations, and embankments, offering a cost-effective method for in-situ ground improvement.

- Micro Piles: Miniature drilled and grouted piles used for underpinning existing foundations, seismic retrofits, and load transfer in areas with restricted access.

These products are designed to work seamlessly with Saskarc’s existing bracing and shoring systems, offering clients a fully integrated approach to excavation support and ground engineering challenges.

Features:

- Design-smart anchoring systems tailored to site-specific ground conditions, loading demands, and excavation geometry.

- Engineered for superior performance and reliability, featuring a critical core component: Canada-made thread bar.

- Fully integrated solutions that coordinate seamlessly with shoring, bracing, and excavation sequencing.

- Constructability-led designs that account for drilling access, installation angles, and field tolerances from the outset.

- Repeatable, well-defined installation details that minimize site modifications and reduce execution uncertainty.

Speed of installation:

- Three-dimensional models provide clear, visual installation plans that eliminate guesswork in the field.

- Upfront planning of access and sequencing enables efficient drilling and anchoring operations with fewer delays.

- Faster anchoring installation allows excavation activities to advance sooner while maintaining stability and safety.

Ground Anchoring Solutions

(Tiebacks. Tiedowns. Soil Nails. Micropiles)

infraMOD’s ground anchoring solutions are engineered to reduce risk, simplify installation, and support faster, more predictable excavation progress.

The new infraMOD ground anchoring and bracing solutions include:

- Temporary & Permanent Strand Anchors: High-capacity anchors designed for shoring walls, retaining structures, and slope stabilization.

- Tie Downs & Tie Backs: Engineered systems for securing structures against uplift and lateral forces, essential for foundations, towers, and industrial facilities.

- Soil Nails: A full range of soil nail systems for reinforcing cut slopes, excavations, and embankments, offering a cost-effective method for in-situ ground improvement.

- Micro Piles: Miniature drilled and grouted piles used for underpinning existing foundations, seismic retrofits, and load transfer in areas with restricted access.

These products are designed to work seamlessly with Saskarc’s existing bracing and shoring systems, offering clients a fully integrated approach to excavation support and ground engineering challenges.

Features:

- Design-smart anchoring systems tailored to site-specific ground conditions, loading demands, and excavation geometry.

- Engineered for superior performance and reliability, featuring a critical core component: Canada-made thread bar.

- Fully integrated solutions that coordinate seamlessly with shoring, bracing, and excavation sequencing.

- Constructability-led designs that account for drilling access, installation angles, and field tolerances from the outset.

- Repeatable, well-defined installation details that minimize site modifications and reduce execution uncertainty.

Speed of installation:

- Three-dimensional models provide clear, visual installation plans that eliminate guesswork in the field.

- Upfront planning of access and sequencing enables efficient drilling and anchoring operations with fewer delays.

- Faster anchoring installation allows excavation activities to advance sooner while maintaining stability and safety.

“They don’t just take a spec and build it. They ask smart questions and bring better ideas to the table.”

“They provided us with the support we needed during the design phase to develop the correct solutions.”

“They’re a partner, not just a vendor. There’s mutual respect and a willingness to adapt.”

“They’re respectful, easy to deal with, and deliver what they say they will. That makes a difference.”

“I didn’t have to chase them. They gave me total peace of mind.”

“Our relationship has become an important partnership.”

Some key projects

Project Feature

PROJECT FEATURE

OTHER AREAS WHERE WE SPECIALIZE

Modular Vehicular

Bridges